Support people with the power of technology, working towards the realization of a future where we are close to people’s hearts

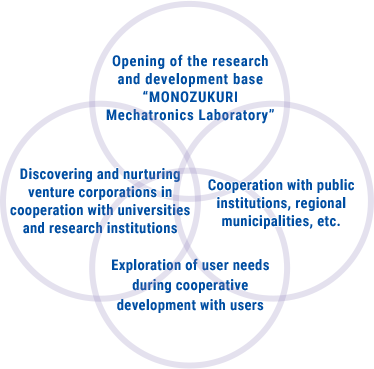

In recent years, the central pivot of monozukuri has been changing significantly. Amid heightened opportunities for cooperation with industry, academia and the government, the Kikuchi Group opened, in as early as 2006, the “MONOZUKURI Mechatronics Laboratory” as a research and development base. Revolving around the said base, research and development initiatives are made in cooperation with universities and research institutions. Furthermore, we make efforts to discover venture corporations that we can cooperate with to create new businesses, focusing on investing and nurturing such businesses.

Initiatives of the Kikuchi Group to realize the “creation of a support industry”

With this goal in mind, we aim for the realization of a more abundant society that is kinder to humans, by being close to people’s hearts and creating products that support people, through steady monozukuri based on established technologies.

The origin and driving force of Kikuchi’s “monozukuri” is the realization of a society that provides optimal support to each and every person.

Construction of a Kikuchi Group platform

Besides the development, prototyping and mass production processes of monozukuri, we are constructing a structure that provides total support to ventures, including the verification, sales and maintenance processes. We are promoting the WORLD ROBOTEC website. With established creativity, we will expand the Kikuchi Group’s capabilities in line with the growth of ventures that we are cooperating with.

Product List

- Wearable Robot

Muscle Suit

Wearable robot for reducing burden

on the lower back using artificial

muscles.Developed by : Innophys Co., LTD

Conducts the development, production and sales of operations supporting robots, etc.WALK-MATE ROBOT

Robot assistant that provides

walking support to those with

unstable walking and moving

rhythms, such as those with

Parkinson’s diseaseDeveloped by : WALK-MATE LAB Co., Ltd.

Conducts the development, production and sales of robots that assist walking, etc.- Field Robot

Drones

Conducts regular

inspection of the

infrastructural network,

monitoring and security of

facilities and the city area,

investigation and analysis of

disaster areas, etc.Developed by: Autonomous Control Systems Laboratory Ltd.

Conducts the development, production and sales of dronesOctopus

Unmanned operational

robot with 4 arms and

4 legs that is utilized

to save lives, remove

debris, etc.

at places with complex landforms,

narrow disaster sites, etc.Developed by: Future Robotics Co. Ltd

Conducts the development, production and sales of remote control operational robots, etc.

- Service Robot

“Concierge”autonomous

mobile service robotRobot that supports operations

by providing guidance,

conducting transportation, etc.

at restaurants, warehouses, etc.Developed by: SOCIAL ROBOTICS Co., Ltd.

Conducts the development, production and sales of service robots, etc.

- Sophisticated Medical Robot

Medical 3D-AR System

A medical device system that

presents ultrasound diagnostic

images in 3D on a head-mounted

display using augmented

reality (AR) technologyDeveloped by: TCC Media Lab Co., Ltd.

Develops medical device systems

- Manufacturing Equipment (Self-developed)

Hot Chamber Aluminum

Die Casting

(Aluminum Hot

Chamber)Hot chamber aluminum

die casting is an innovative

technology that makes it

possible to cast pure aluminum,

something impossible with conventional aluminum die casting technology (cold chamber aluminum die casting).

Use of pure aluminum improves heat conductivity, resulting in higher heat dissipation per unit area when compared with conventional aluminum die casting technology.

The new technology also makes surface processing easier and helps to reduce costs, while low-pressure casting, a feature of the hot chamber technology, enables precision and thin-wall casting.

What tuned all these features into reality is the hot chamber aluminum die casting machine that Kikuchi Seisakusho had developed.

Kikuchi Seisakusho is exploring applications such as casting for power semiconductor devices that require a high level of heat dissipation and external components of high-tech equipment, which used to require cutting operation.Six-axis Parallel Link

The six-axis parallel link can

position the stage, which

has six actuators fixed on

it, precisely at any point in

three-dimensional space.

It has been used for robot arm

control.

Kikuchi Seisakusho is using this mechanism to develop a pipe bender that can bend pipes three-dimensionally and a device that offer precision positioning.

By using dedicated dies that we produced, the pipe bender succeeded in bending not only round pipes but also square, rectangular, uneven, and other irregularly shared pipes.

- Micro Device

Metal Micro Pumps (MMP)

Metal micro pumps, which handle

a minute amount of fluid, are a

compact pump made of stainless

steel film.

The micro pump can be used to transport fluids or gases with different viscosities.

As it is made of stainless steel, it can be produced at a lower cost than conventional pumps made of silicon wafers.

The metal micro pump is expected to be used for key devices such as medical devices and fuel cells. Kikuchi Seisakusho is also considering using it for robots, wearable units and other applications. As technologies related to environment, energy and healthcare attract attentions, the metal micro pump is expected to be brought to various markets.