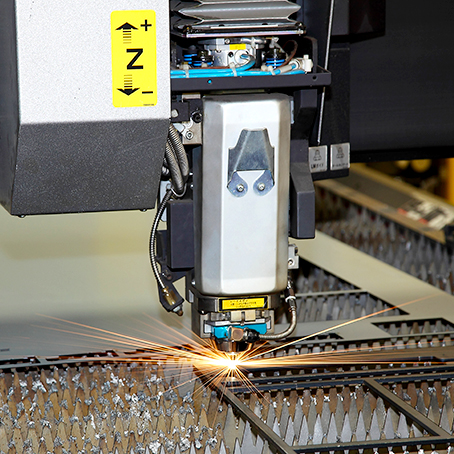

Precise Sheet-Metal Processing

Precise sheet-meet processing encompasses an extensive range of applications, from very small precision articles to large sheet metal, using equipment such as a carbon dioxide gas laser, NC turret lathe press (no-nibbling available), and special wire EDM. This processing approach also has the technology and the equipment power to meet demands for high accuracy and quick turnaround. Overall cost savings are possible through the combination of press technology and sheet metal technology, for each stage from prototypes to volume production. Precise sheet-metal processing is one of the core technologies of the Kikuchi Group.

Precision Press Processing

Since it first manufactured precision press components for wristwatches in 1974, the Kikuchi Group has accumulated sophisticated tool & die processing and press technologies. We can process metal sheets to thicknesses in the tens of microns, as well as highly complex deep-drawn products using the transfer press, etching transfer press, and foot press.

Kikuchi has a Makino wire-electrical discharge machine and an NC electrical discharge machine, and is able to offer high-speed machining for micro processing. We also have dozens of press machines, with maximum handling of 300 tons. With these facilities, Kikuchi can respond to customer requirements from trial manufacture to volume production.

Moreover, in cooperation with Kikuchi (HONG KONG) LTD, we can process press tool production and press working in China.